What is the 2024 problem in logistics?(Japan)

The 960-hour overtime cap for truck drivers and the Revised Standards for Improvement Notification will be applied from April 2024, and there are concerns that shorter working hours will result in insufficient transportation capacity and the possibility that “goods cannot be transported,” and this is known as the “2024 problem in logistics.

<Quote:All Japan Trucking Association>

What I think about when I’m working

Speaking for myself, I have recently been put in charge of “receiving and shipping operations.

And I think, the difference between a high workload and a low workload is drastic from day to day.

It’s like riding a road bike up Mt. Haruna Hill Climb and Mt. Olympus on different days!

<Quote: Mt. Haruna Hill Climb in Takasaki HP>

<Quote:Wikipedia(<\Mount Qlympus)>

Why? I thought to myself why this situation is the way it is, I recalled the records/memories of my past food retail business

Stock up on average! Don’t make waves!

‘Stock up on averages! Don’t make waves!” These words came to me when I was working in the food retail industry, I heard this advice from a supplier when I was working at a food retailer.

When you hear these words alone, you may think, “What the heck is that?” You may be thinking, “What does it mean? It is the advice to “balance your weekly purchasing volume with an average.

He was a hard-spoken person, but I learned a lot from him because of his honest and undisciplined personality.

Is he still alive and well?

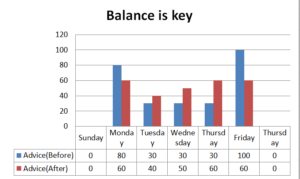

Advice graphically illustrated

Blue bar line is how to purchase before advice

- We purchase less on weekdays due to low sales, and purchase more on Fridays for Saturday and Sunday, when we make the most money on the weekends.

- The reason for the large number of Monday’s is to compensate for the lack of inventory at the beginning of the week.

Red bar line is how to purchase after advice

- We purchase weekend sales (Saturday and Sunday) in advance on weekdays.

- The reason Monday is a little low is because we are stocking up in anticipation of Friday.

- We had to reduce stocking on Tuesdays because of holiday staff.

Reading from the graph, we see a 40% decrease in the maximum number of purchases.

- The warehouse can be made smaller (less maintenance and management) because the maximum purchase volume is reduced.

- Reduce the number of transportation vehicles (trucks, etc.)

- No (or reduced) redundancy

- Human load becomes average.

Logistics will be based on peaks.

Then imagine this. On weekdays, the warehouse is skunked and trucks that don’t move are sitting in the parking lot.

However, considering peak hours, we cannot make our warehouse smaller or reduce the number of trucks.

As a result, inefficient costs come around and come to all of you.

Naturally, this will induce accidents and mistakes, and lead to a great march of improvement in response.

Addressing the 2024 issue of logistics will benefit ourselves in a broader sense.

Logistics can’t be moved

Manufacturing → moved overseas (cost transfer)

Sales business → Expand sales channels overseas

Logistics industry → we have to solve it ourselves.

Logistics serves as the blood in the human body as an analogy.

If necessary nutrients are not transported, the human body will malfunction.

Now that I think about it, I used to be narrow-minded and pointed with baseless confidence.

I am now grateful to the person in charge of my supplier who gave me such a sermon!

At the time, I thought to myself, “Damn! That’s so annoying! But….

[Sponsor Links]

コメント Comment